[ TECH ] Understanding the Physics of the Balance Wheel and Hairspring

In the realm of horology, the balance wheel and hairspring (or balance spring) are often referred to as the heart of a mechanical watch. These components work together as the primary regulating system, responsible for the accurate timekeeping of the watch. But how exactly do they function, and what role do they play in ensuring that your watch ticks with precision? To understand this, we need to dive into the physics behind the balance wheel and hairspring assembly.

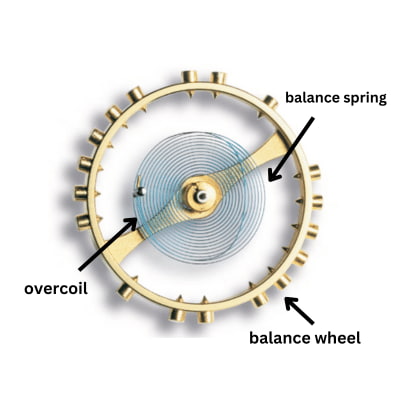

What is the Balance Wheel?

The balance wheel is a small, wheel-shaped component that oscillates back and forth in a controlled, repetitive motion. It acts as the timekeeping regulator of the watch, working in tandem with the hairspring to regulate the release of energy from the mainspring. This oscillating motion divides time into consistent, measurable intervals, typically one beat per second (1 Hz) or more.

The balance wheel operates similarly to a pendulum. Just like a pendulum swinging back and forth, the balance wheel oscillates with a regular period. The key difference, however, is that the motion of the balance wheel is regulated by a hairspring, a fine spring that restores the wheel to its equilibrium position after each swing.

The Role of the Hairspring

The hairspring is a delicate spiral spring that is attached to the balance wheel. It serves two primary functions: to provide restoring force and to regulate the period of oscillation of the balance wheel. The hairspring works on the principle of Hooke’s Law, which states that the restoring force exerted by a spring is proportional to the displacement from its equilibrium position. This force is essential for the balance wheel to return to its starting point after each oscillation.

Hooke’s Law:

F = -kx

Where:

- F is the restoring force,

- k is the spring constant,

- x is the displacement from equilibrium.

In an ideal system, the balance wheel’s motion would be perfectly periodic, meaning it would oscillate at a constant frequency. However, external factors such as temperature, friction, and magnetism can alter this balance, leading to variations in timekeeping accuracy.

The Oscillation Process: How It Works

Energy Transfer: The mainspring, which is wound up manually or by automatic movement, stores energy and releases it gradually through the gear train.

Impulse: This energy is delivered to the balance wheel via an escapement mechanism (such as the Swiss lever escapement), which provides small, controlled impulses that push the balance wheel into motion.

Oscillation: Once the balance wheel is in motion, the hairspring provides a restoring force that brings the wheel back to its equilibrium position. The balance wheel oscillates back and forth with each swing taking a precise amount of time, thanks to the resistance and elasticity of the hairspring.

Energy Release: Each swing of the balance wheel releases energy at a consistent rate, which in turn powers the movement of the watch hands, translating these oscillations into accurate timekeeping.

(image from https://www.jewelsbylove.com/)

Frequency and Amplitude

The frequency of the balance wheel’s oscillation, measured in hertz (Hz), is critical to the watch’s accuracy. A mechanical watch typically operates with a frequency between 2.5 Hz (18,000 vibrations per hour or vph) and 5 Hz (36,000 vph). The higher the frequency, the more oscillations occur per unit of time, leading to a finer division of time and improved accuracy.

Amplitude, on the other hand, refers to the extent of the balance wheel’s oscillation. If the amplitude is too high or too low, the timekeeping will be inaccurate. The balance wheel needs to oscillate within a specific range of amplitude to ensure precise time measurement.

How External Factors Affect the Balance Wheel and Hairspring

While the balance wheel and hairspring assembly works well in an ideal environment, real-world conditions can interfere with its performance. Some of the most common disruptors include:

1. Temperature

- Thermal Expansion: The materials used in the hairspring and balance wheel expand and contract with temperature fluctuations. As the temperature increases or decreases, the elasticity of the hairspring can change, altering the period of oscillation and leading to timekeeping errors.

- Compensated Balance Wheels: To address this, modern watchmakers use materials such as bimetallic or Nivarox alloys, which are designed to minimize the effects of temperature on the balance wheel and hairspring.

2. Magnetism

- Magnetic Fields: Magnetic fields can induce magnetization in ferromagnetic materials, such as the steel in traditional hairsprings. This can distort the shape and elasticity of the hairspring, causing it to behave non-linearly and affecting the oscillation frequency. Here I go more in depth on this

- Anti-Magnetic Materials: In response, manufacturers have developed anti-magnetic materials, such as silicon and paramagnetic alloys, which are immune to the effects of magnetism, ensuring the watch’s accuracy even in environments with strong magnetic fields.

3. Friction

- Mechanical Resistance: Friction between the balance wheel pivot and the surrounding jewels or the hairspring’s coils can cause energy losses, affecting the amplitude and frequency of oscillation. Proper lubrication and the use of high-quality components can minimize these effects.

4. Shock

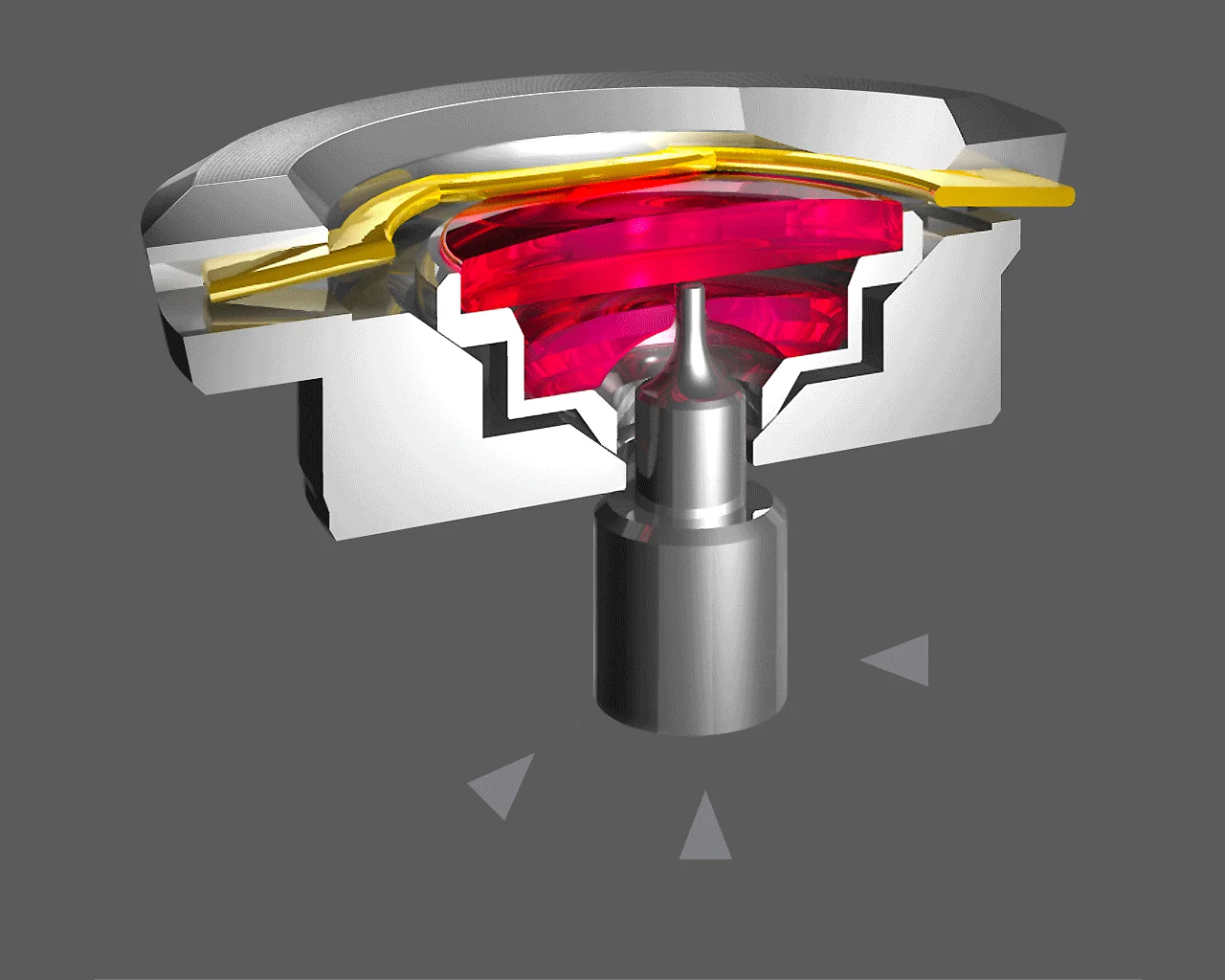

- Impact: Physical shocks or impacts can disrupt the oscillation of the balance wheel, leading to inaccuracies or even damage. To protect against this, many high-end watches feature shock-absorbing mechanisms like the Incabloc system, which helps cushion the balance wheel and prevent damage during sudden movements.

Image: An example of a shock-absorbing mechanism used in watches to protect the balance wheel

Material Science and Modern Innovations

Modern advancements in materials science have greatly enhanced the performance of the balance wheel and hairspring system. Some of the most notable innovations include:

Silicon Hairsprings: Silicon is a diamagnetic material, meaning it is unaffected by magnetic fields. Watches with silicon hairsprings (e.g., OMEGA’s Master Chronometer) are highly resistant to magnetism, offering improved accuracy and durability.

Beryllium and Bimetallic Balance Wheels: These materials are used to create balance wheels that are more resistant to temperature variations, reducing the impact of thermal expansion on the timekeeping.

Nivarox Alloys: These are special alloys designed for use in hairsprings, with improved resistance to temperature fluctuations and magnetic fields, ensuring long-term precision.

(image from https://www.uhrenkosmos.com/)

(image from https://www.uhrenkosmos.com/)

Conclusion

The balance wheel and hairspring are the beating heart of a mechanical watch. Through the delicate interplay of materials, physics, and mechanical design, they regulate time with remarkable precision. Understanding the principles of oscillation, restoring forces, and the various factors that influence their performance provides a deeper appreciation for the complexity and craftsmanship involved in watchmaking. Modern advancements continue to refine these systems, ensuring that mechanical watches remain as accurate and reliable as ever, even in the face of environmental challenges.

By gaining a greater understanding of the physics behind the balance wheel and hairspring, we can better appreciate the fine-tuned mechanics that allow these remarkable timepieces to function with such precision and artistry.